Advanced Materials Driving Automotive Innovation

Improvements in advanced materials are helping to drive automotive innovation as manufacturers work towards the development of safer and more sustainable vehicles.

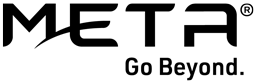

From the horse-drawn carriage to modern electric vehicles (EV), the development of new materials continues to play an integral role in boosting automotive performance, economic viability and safety. Government fuel efficiency mandates now require automakers to improve the performance of smaller engines, reduce vehicle weight, and increase the proportion of hybrid and EV units sold. The next phase of innovation centers on improving safety and reducing traffic congestion through electronics and sensors for ADAS (advanced driver assistance systems), and 5G network integration of autonomous vehicles. New materials can even help reduce the perennial hazards of driving at night and in inclement weather.

New materials help improve vehicle safety and lower emissions

While sustainability goals have driven the electrification of the modern vehicle’s drivetrain, the automotive industry’s pursuit of innovation has similarly driven improvements in the electronic components of the modern vehicle. From improved communication technologies to increasingly-complex electronic dashboards capable of providing drivers with critical information, digital sensors and improvements in modern technologies are enabling vehicle autonomy.

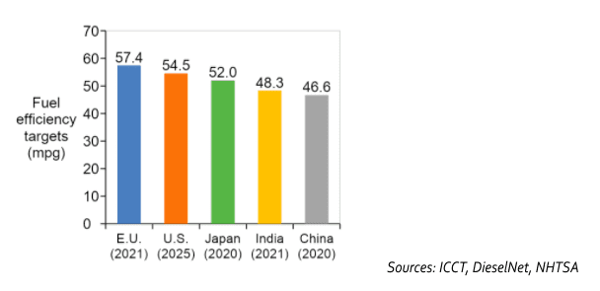

ADAS, driver-assist features — automated functions that preview the age of increasingly autonomous vehicles — are being pushed by OEMs primarily for safety and consumer convenience reasons. One study by the Swedish insurance company Volvia, for example, showed Volvo cars equipped with the City Safety autonomous brake system were involved in approximately 20 percent less rear-end collisions than cars without the technology.

Lux Research forecasts significant traction for basic autonomy and enhanced autonomy. A welcome side benefit of vehicle automation is increased fuel efficiency, due to smoother and more predictable braking and acceleration — up to a 10 percent improvement compared to a human drive, according to studies by OEMs like Porsche.

The Society of Automotive Engineers (SAE) has defined six levels of vehicle automation. Level 0 vehicles may have cruise control, but the driver performs all driving tasks. Level 1 includes features such as adaptive cruise control or lane keeper. Level 2 vehicles have partial automation; the driver must have hands on the wheel, but the system can control speed and steering in conditions such as stop-and-go traffic. Level 3 vehicles are capable under ideal conditions, but the driver must be ready to take over at any time. Level 4 vehicles are fully autonomous under known conditions, with optional driver control. Level 5 vehicles may even eliminate the steering wheel and pedals.

Automotive innovations sourced from outside the industry

Materials in vehicle components including windshields, driver displays, and communications systems are helping to enable new capabilities in the automotive industry. As indicated by Research and Markets, innovations from outside enterprises are often developed and proven before being adopted by major manufacturers. “The automotive component industry is characterized by a high level of diversity, creativity, and flexibility. It includes technological solutions ranging from commercially viable and mass-produced automotive products to experimental technologies that are in the early stages of being transferred from academic and private research.”

As major auto manufacturers continue to embrace innovations from outside the industry, companies such as META – Metamaterial (CSE:MMAT) are working to develop ultra-lightweight materials with new capabilities that could be applied to the automotive industry. In order to develop relationships with auto manufacturers, META has signed a partnership with Crossover Solutions, a global provider of technical solutions with experience in Tier 1 automotive and aerospace supply chains.

META’s solutions feature two core technologies

The breakthrough performance being offered by Metamaterial is enabled by proprietary tools and methods to design nanostructured film components using two core technologies: large-area holography and nanolithography. Holography is a technique where collimated visible wavelength lasers are used to directly write an interference pattern inside the volume of light-sensitive, photopolymer material in order to offer highly transparent optical filters and holographic optical elements. Lithography is a widely-used process, for example, to create dense nanoscale patterns on semiconductor wafers. META’s proprietary Rolling Mask Lithography (RML®) scales to much larger substrates, with deep-submicron precision over meters squared on any glass or plastic surface, dramatically reducing cost per square meter.

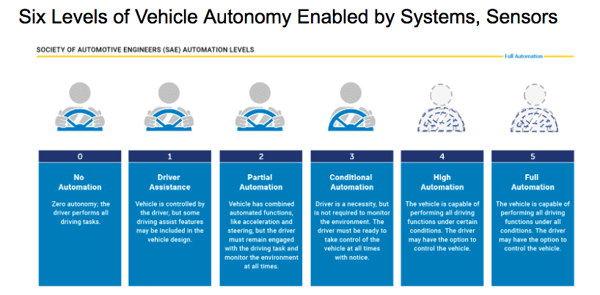

Holographic optical combiners for heads-up displays

META has developed a holographic optical combiner that can create a heads-up display (HUD) capable of superimposing light from a projector system onto light from the outside world. The combiner achieves the paradoxical requirement of maintaining transparency to admit light from the road while preserving reflectivity to maximize the coupling efficiency of the projector.

“Using a projector that is tuned to a certain light frequency, the film we produce can reflect only the light from the projector back to the user. This allows the viewer to see the projected image while seeing through to film to everything on the outside. It’s similar to an augmented reality display,” said Gardner Wade, Chief Product Officer at META. “In the automotive world, this can be used for instrumentation panels so the driver can keep eyes on the road while seeing key instruments and status updates including engine RPM, speed, or alerts from integrated night vision systems.”

Improving Lidar performance, ease of integration

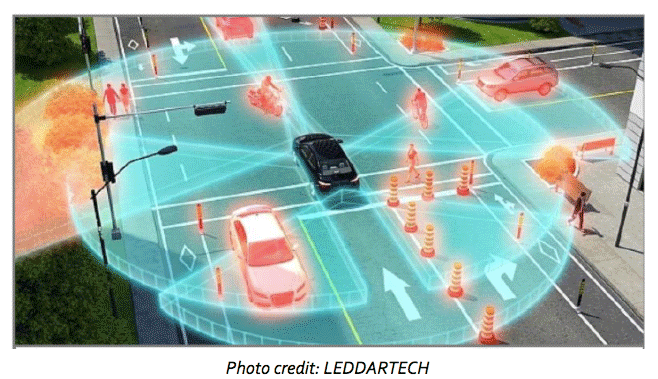

Another application of holography is in Lidar (Light Detection and Ranging), an advanced sensor that uses laser light pulses to map the surroundings of an autonomous vehicle. META is developing a solution that combines existing MEMS technology with a 2D spatially-modulated hologram grating. This approach can enhance the range of Lidar scanning, while improving the compactness of the system with flat optics, making the sensors easier to integrate into vehicle designs. META is pursuing partnerships with Lidar manufacturers.

Lidar is a Critical Component in Autonomous Vehicles

Transparent conductive metal mesh has multiple uses

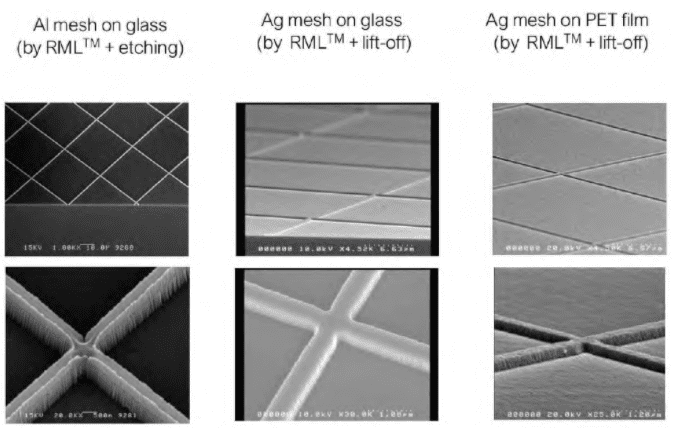

Another product from META is a proprietary material called NanoWeb®. It is a transparent metal mesh, which can be fabricated using different metals such as silver or aluminum on glass or plastic substrates. The submicron feature size is so small (150 nanometers) that it is invisible to the human eye, while the mesh remains highly conductive. NanoWeb ® is conformable, so it can be applied to curved surfaces, such as headlights or camera lenses. Applications include heating elements for de-icing and de-fogging of windshields, headlights and sensors, sensors for touchscreen displays, and transparent antennas for 5G communications.

Examples of NanoWeb® nanostructures:

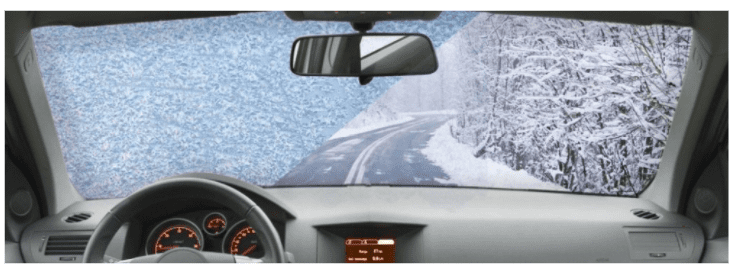

Integrated de-icing, de-fogging improves vehicle design

The typical defrost setting built into vehicle climate control systems directs forced air from the heater through ducts below the windshield. Performance is slow, and under extreme conditions may not prevent snow and ice buildup on the windshield wipers. Integrated conventional heating elements are often used only on the margin of the windshield, or on rear windows because they obscure the driver’s vision. NanoWeb® transparent heaters can deliver up to 10,000 Watts per square meter for rapid and efficient de-fogging or de-icing of windows, headlights, mirrors and sensors. Eliminating ductwork under the dash saves space and reduces vehicle weight, improving fuel efficiency and EV range.

Dashboard Design Streamlined with Integrated Windshield De-Icing

“A key challenge in integrating metal mesh heating elements on windshields or windows is to do so without impairing communications. A conductive metal mesh may effectively create a Faraday cage, blocking the reception of desired signals. NanoWeb® has the unique ability to be a passband while at the same time working as a transparent heater, allowing the desired frequencies to enter the vehicle,” said Wade. Metamaterial has been testing its new product in partnership with the auto industry.

ADAS and autonomous vehicle systems depend on a wide array of cameras and sensors whose performance can be degraded by the buildup of condensation, mist, or ice in extreme winter conditions. A thin, lightweight layer of NanoWeb® material can ensure that critical sensor inputs are not impaired or even disabled by bad weather.

Advanced materials connecting the modern vehicle

Increasingly autonomous modern vehicles need for communications systems to relay information from sensors within the vehicle to both the driver and the outside world. “We can design antennas specific to different frequencies, from radio waves to mmWave 5G,” said Wade. “5G has special constraints requiring more antennas to achieve high data rate connectivity. Nanoweb allows auto manufacturers to integrate antennas into headlights, mirrors and windows without compromising aesthetics or performance.”

Takeaway

The economic success of future vehicles could greatly depend on improving sustainability, connectivity, and safety features. These next-generation vehicles will not only lower emissions but also reduce the significant costs of time and fuel wasted in traffic congestion. In all cases, the materials used in automotive components will play a critical role.

This article was originally published by the Investing News Network in July 2020.